The Difference Between Lifting Hardware and Rigging Hardware

Rigging hardware and lifting hardware play different roles on site, The roles of the two like hands and arm. Lifting and rigging equipment has a function like hands that can firmly grab loads,the difference from hands is that it is made of high strength steel come in multi sizes and types to fix various kinds of loads. As for lifting and rigging equipment, it's more like powerful arms that safely transport loads at a high position and over a long distance. Selecting the correct crane rigging equipment with the hoisting machines can ensure stable movement and placement. Titansuhe is a leading lifting equipment factory in China, manufacturing all lines of lifting hardware and rigging hardware.

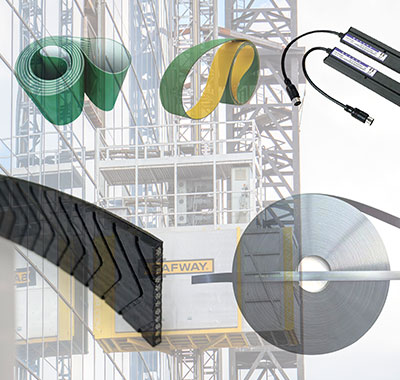

7 Types of Rigging Equipment

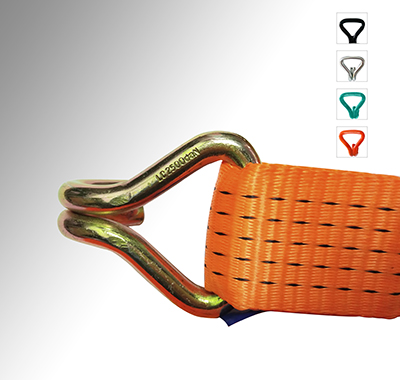

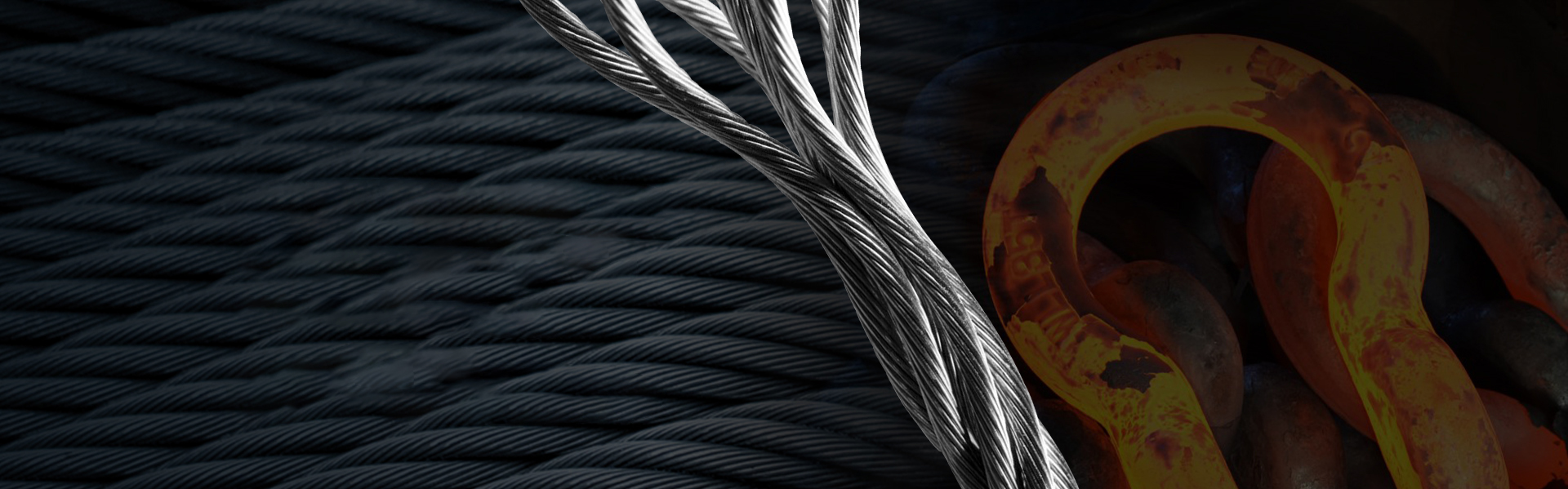

Rigging equipment includes lifting chain shortlinked accessories, chain hook and shackle, wire ropes, slings, turnbuckles, and lifting and lashing points used with manual hoists, electric hoists or cranes.

Lifting and rigging equipment is combined with connecting links, hooks and wire rope, chains or slings. These tools are generally used for carrying and lifting heavy loads. It safely connects the load to the lifting machinery and transports the stacked objects from one place to the place in need. Industries including transportation, fabrication, construction site and marine frequently operate with rigging equipment.

The 7 types of commonly used lifting and rigging equipment are Wire rope and rope accessories, Grade 80 chains and chain components, stainless steel hooks, stainless steel chains and lifting or lashing points. These durable and high quality rigging equipment are applied in a wide range of applications, such as industrial workshops, transportation, oil and gas, and marine and construction sites.