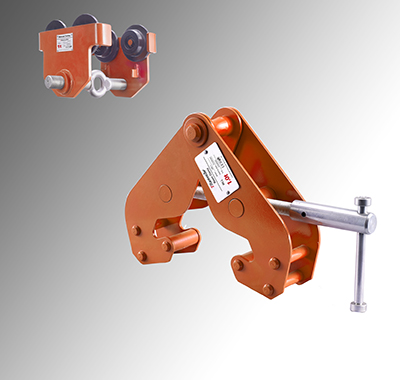

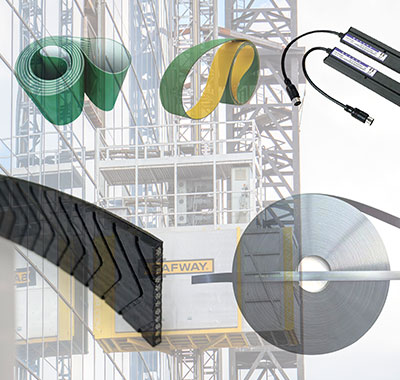

Lifting Tools and Equipment

If you have anything over 100kg that exceeds manpower's ability to lift or move, TITANSUHE's lifting tools and equipment factory can offer professional lifting products to get the job done. You can use one single piece of lifting equipment tools for simple work or some combinations for multiple purposes. The optional hoisting tools and equipment capacity from 100kg to 100000kg can almost cover the lifting requirements in most industries.

Besides the wide range expanding, our biggest advantage is the quality assurance. All of our machine to lift heavy objects is produced strictly according to the ISO9001 system. Every piece of lifting tools and equipment for sale is checked and tested to get its own certificate before packing. If you want to buy lifting equipment, TITANSUHE lifting equipment factory is your best choice. Through these years, TITANSUHE, a professional lifting equipment factory, dedicates itself to the continuous upgrading of our products to provide the safest operation. As all we know, no matter how good the lifting products are, if the operators do not follow up the operation manual, it will cause danger. To protect operators from injury from the wrong operation, we successfully developed our heavy lifting tools with more features such as overload protection, thermal protection, over traveling limit switch, power loss protection, dual braking system, emergency stop, and so on. These features can greatly help these operators that may not be well trained from potential risks. Contact us now for more info about the lifting equipment list and price!