Introduction to Cargo Belt Straps

Cargo belt straps, also known as tie-down straps or lashing straps, are essential tools for securing cargo during transportation. They are designed to provide stability and prevent cargo from shifting, which can cause damage to goods and pose safety risks. These straps are widely used in various industries, such as logistics, trucking, and shipping, ensuring that items remain in place regardless of the transportation method.

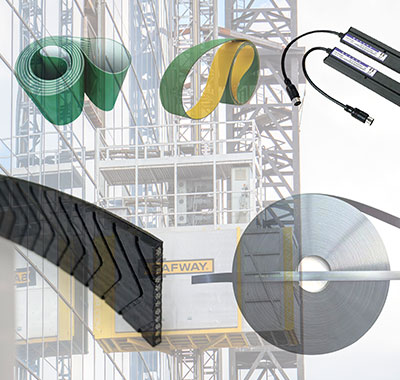

Types of Cargo Belt Straps

There are several types of cargo belt straps, each designed to meet specific needs and applications. Let’s explore the most common types:

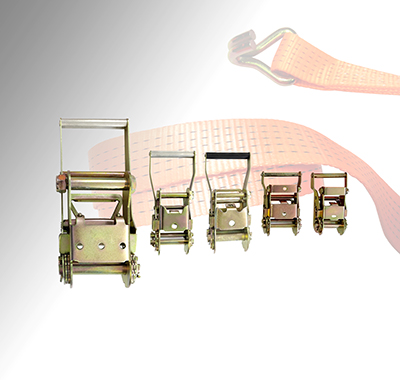

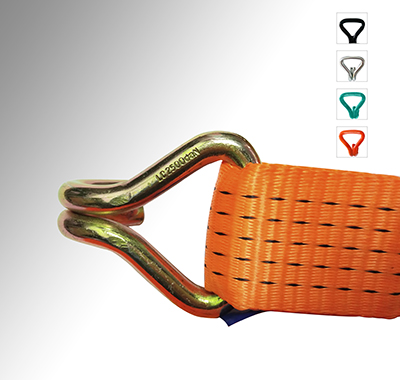

Ratchet Straps

Ratchet strap is perhaps the most widely used cargo belt. They are equipped with a ratcheting mechanism that allows you to tighten the strap with ease, ensuring that the cargo is held securely. These straps are highly durable and can handle heavy loads, making them ideal for commercial trucking and industrial use.

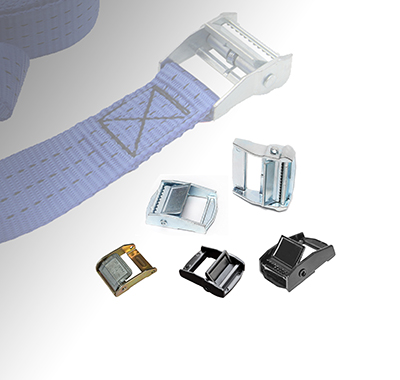

Cam Buckle Straps

Cam buckle straps are a simpler alternative to ratchet straps. They use a cam mechanism to adjust the strap’s tension. These are typically used for lighter loads and are easier to release, making them convenient for quick adjustments and frequent use.

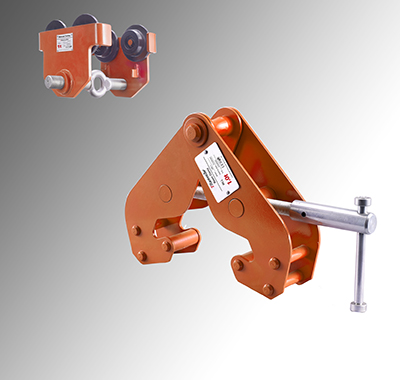

Winch Straps

Winch straps are heavy-duty straps commonly used in conjunction with winch systems on flatbed trucks and trailers. These straps can secure extremely large and heavy cargo, such as industrial equipment or machinery, and are designed to withstand harsh conditions.

Materials Used in Cargo Belt Straps

The material of a cargo belt strap plays a critical role in its strength, flexibility, and durability. Below are some common materials used:

Polyester

Polyester is the most common material used in cargo belt straps due to its strength, low stretch properties, and resistance to moisture and UV damage. Polyester straps are ideal for securing heavy loads and are frequently used in both trucking and shipping industries.

Nylon

Nylon straps are known for their elasticity and ability to absorb shock. While they are strong, they tend to stretch under tension, which can make them less suitable for securing very heavy or delicate cargo. However, they are excellent for use in situations where slight flexibility is needed, such as in off-road or recreational transport.

Polypropylene

Polypropylene straps are lightweight and cost-effective, making them suitable for lighter loads. However, they are not as durable as polyester or nylon straps and are best suited for short-term or low-stress applications.

Applications of Cargo Belt Straps

Cargo belt straps are used in a wide range of applications, from industrial shipping to personal projects. Here are some of the most common uses:

Commercial Trucking

In the trucking industry, cargo belt straps are used to secure everything from pallets to large machinery. Ratchet straps, in particular, are favored for their strength and ability to keep cargo stable during long hauls.

Shipping Containers

Shipping containers often carry a wide variety of goods across long distances. Cargo belt straps ensure that goods inside the container stay in place and prevent movement that could lead to damage or accidents.

Air Cargo

Air cargo requires extra care due to the nature of air travel. Cargo belt straps help secure goods in place, reducing the risk of shifting due to turbulence or changes in pressure.

Personal Use

Cargo belt straps are also used by individuals for personal projects, such as securing furniture or other large items during a move. Cam buckle straps are often used for lighter loads in personal vehicles or for short-distance transportation.

Conclusion

Cargo belt straps are indispensable tools for ensuring the safe and secure transport of goods. From commercial trucking to personal use, these versatile and durable straps provide peace of mind by keeping cargo stable throughout the journey. By understanding the different types of straps, materials, and applications, you can select the right strap for your needs and ensure that your cargo arrives at its destination safely.