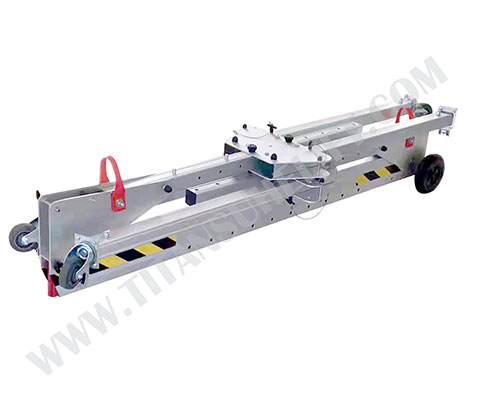

Aluminum Portable Gantry Crane Features and Advantages

All-Aluminum Construction- With light weight, but high performance including the aluminium gantry beam.

Clean and Corrosion Resistance-Can be used in clean room and some harsh environments

All-Folding-Structure-Can be break down for easy stock and carry, low transportation cost

4-Bolts Connection for Assembly and Height and Clear Span Adjustment- Enable Quick setup and break down, 2-3 minutes to finish foot support

One-wrench and one person operation-Assembly and disassembly for 250kg capacity, no other equipment or tools needed

Bolted Construction, Cheek Plates, End Plates and Solid Leg Structure-Enable this adjustable aluminum gantry crane move freely and safely under rated load.

Four Position Swivel-Lock Casters-360-Degree rotated heavy duty caster provide excellent floor protection and can be maneuvered over rough or uneven surfaces.

Super Lightweight-allows this aluminum gantry crane for sale to be shipped easily to a job site and even carried up a ladder or staircase to a rooftop work area.

Still not find the gantry crane you want, you can contact Titansuhe lifting equipment factory for more custom solutions.

Why Use Aluminium Portable Gantry Crane ?

Aluminum portable gantry cranes are versatile lifting devices that are designed to be lightweight, durable, and easy to move from one location to another. Here are some of the advantages of using an aluminum portable gantry crane:

Lightweight: Aluminum is a lightweight material that makes portable gantry cranes easy to move and position. This can be especially beneficial for operations that require frequent setup and dismantling of equipment.

Durable: Despite its lightweight, aluminum is a strong and durable material that can withstand heavy loads and harsh environments. This makes aluminum portable gantry cranes a reliable choice for lifting and moving equipment and materials.

Corrosion-resistant: Aluminum is resistant to corrosion, making it ideal for use in outdoor environments where it may be exposed to moisture or other corrosive substances.

Easy to assemble and disassemble: Aluminum portable gantry cranes are designed to be easy to assemble and disassemble, which can save time and reduce labor costs.

Adjustable height: Many aluminum portable gantry cranes are height-adjustable, which can be useful for lifting loads of different sizes and shapes.

Versatile: Aluminum portable gantry cranes can be used in a variety of settings, including construction sites, factories, warehouses, and shipping yards. They are suitable for lifting equipment, materials, and even personnel.

Overall, aluminum portable gantry cranes offer a lightweight, durable, and versatile solution for lifting and moving heavy loads in a variety of settings.

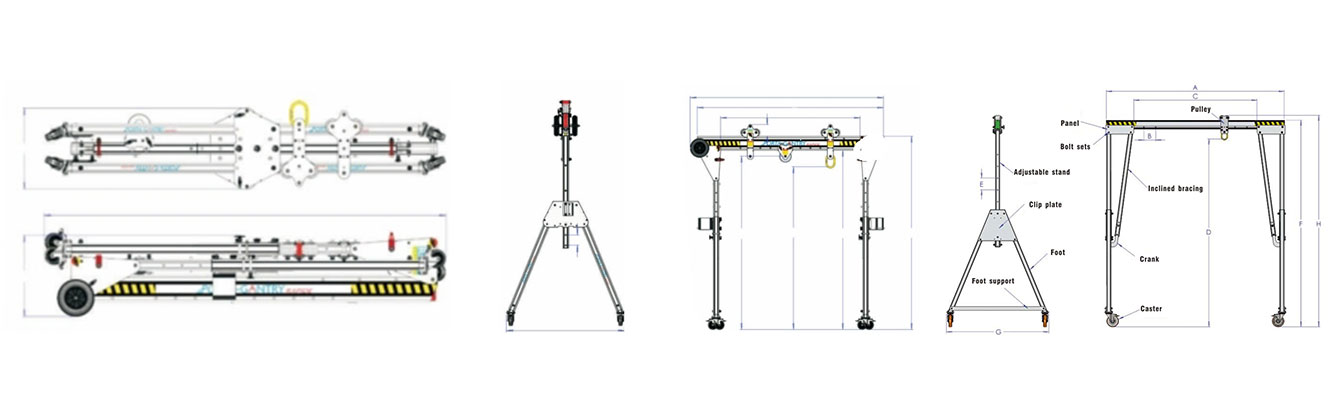

How to Assemble An Aluminum Gantry Crane

Here are the general steps for assembling an aluminum gantry crane for sale:

Unpack and inspect all parts: Before beginning assembly, make sure all the parts are present and in good condition. Follow the manufacturer's instructions for unpacking and inspecting the parts.

Assemble the legs: Start by assembling the legs of the gantry crane. Attach the caster wheels or pads to the bottom of the legs if required.

Install the crossbar: Connect the legs with the crossbar. The crossbar should be centered and level with the help of a spirit level.

Attach the hoist: Install the hoist on the crossbar or beam according to the manufacturer's instructions. Be sure to attach the hoist securely and test it before use.

Connect the braces: Connect the braces to the legs and the crossbar to provide additional stability.

Install the trolley: If the gantry crane comes with a trolley, install it on the beam or crossbar. Make sure it is attached securely.

Secure the assembly: Check that all bolts, nuts, and screws are tight and secure. Double-check that the crane is level and stable.

Test the crane: Test the crane with a light load before using it for heavier loads. Follow all safety precautions and manufacturer's instructions when using the crane.

It is important to follow the manufacturer's instructions carefully when assembling the gantry crane, as the assembly process may vary depending on the specific model and brand. If you are unsure about any step of the assembly process, seek the help of a qualified professional.

Adjustable Aluminum Gantry Crane Application

Adjustable aluminum gantry cranes have a variety of applications in different industries due to their flexibility, lightweight, and ease of use. Here are some of the most common applications for adjustable aluminum gantry crane for sale:

Manufacturing: Gantry cranes can be used for lifting and moving heavy equipment and materials in manufacturing plants, including assembly lines and production floors.

Construction: They are used for lifting and moving construction materials and equipment on job sites, such as steel beams, piping, and concrete blocks.

Maintenance and Repair: Gantry cranes can be used for maintenance and repair work on large machinery, such as engines, turbines, and generators.

Warehouse and Storage: Gantry cranes are used for lifting and moving heavy items in warehouses and storage facilities, including pallets, crates, and machinery.

Event and Entertainment: Adjustable aluminum gantry cranes can be used in the event and entertainment industry for setting up stages, lighting, and sound equipment.

Transportation: They can be used in transportation for loading and unloading of heavy items, such as cargo containers and shipping crates.

Adjustable aluminum gantry crane for sale are versatile and can be customized to suit the specific needs of different industries and applications. They provide a safe and efficient solution for lifting and moving heavy loads, reducing the risk of accidents and injuries in the workplace.